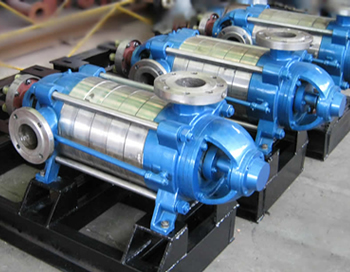

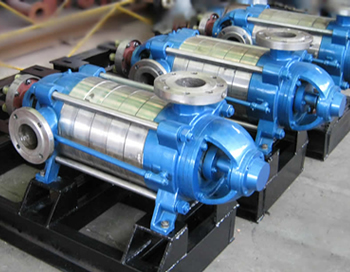

D, DF type stainless steel horizontal multistage centrifugal pump

D-type stainless steel horizontal multi-stage centrifugal pumps are used for industrial and urban water supply and drainage, high-rise buildings, garden sprinkler irrigation, fire pressurization, heating, heating and cooling water circulation pressurization and equipment matching, etc., especially suitable for small boiler water supply.

Structural features:

The D series multistage centrifugal pump is a multistage segmented type. Its suction port is located on the water inlet section and is horizontal, and the discharge port is vertically upward on the water section. Its head can be increased or decreased according to the needs of use. Whether the pump is assembled well or not has a great influence on performance, especially the outlet of each impeller and the in and out center of the guide vane. A slight deviation will reduce the flow of the pump and reduce the head. The efficiency is poor, so be sure to pay attention when overhauling and assembling .

The main parts of D series multistage centrifugal pumps are: inlet section, middle section, outlet section, impeller, guide wing baffle, outlet section guide wing, shaft, sealing ring, balance ring, shaft sleeve, tail cover and bearing body.

The inlet section, the middle section, the guide vane baffle, the outlet section guide wings, the outlet section and the tail cover are all made of cast iron, which together form the working chamber of the pump.

The impeller is made of cast iron with blades inside, and the liquid enters on one side along the axial direction. Because the impeller is unequal before and after the pressure, there must be an axial force. This axial force is borne by the balance disc. The impeller undergoes a static balance test when it is manufactured.

The shaft is made of carbon steel, with an impeller in the middle, and is fixed on the shaft with a key, a shaft sleeve and a shaft sleeve nut. One end of the shaft is equipped with a coupling part, which is directly connected to the motor.

The sealing ring is made of cast iron to prevent the high-pressure water of the pump from leaking back into the water inlet part. They are respectively fixed on the inlet section and the middle section. They are vulnerable parts and can be replaced with spare parts after wear.

The balance ring is made of cast iron and is fixed on the outlet section. It forms a balance device with the balance.

The balance plate is made of wear-resistant cast iron and is mounted on the shaft between the water outlet section and the tail cover to balance the axial force.

The shaft sleeve is made of cast iron and is located in the packing chamber. It is used to fix the impeller and protect the pump shaft. It is a vulnerable part and can be replaced with spare parts after wear.

The bearing is a single-row radial ball bearing, which is lubricated with calcium-based grease.

The packing functions as a seal to prevent air from entering and a large amount of liquid leakage. The packing seal is composed of the water inlet section and the packing chamber on the tail cover, packing gland, packing ring and packing, etc. A small amount of high-pressure water flows into the packing chamber to act as a water seal. The tightness of the filler must be appropriate, not too tight or too loose, and the liquid can seep out drop by drop. If the packing is too tight, the sleeve will easily generate heat and consume power. If the packing is too loose, the efficiency of the pump will be reduced due to the loss of liquid.

Product features of D series multistage centrifugal pump:

1. The hydraulic model has high efficiency and wide performance range.

2. The pump runs smoothly and has low noise.

3. The shaft seal adopts soft packing seal or mechanical seal, the seal is safe and reliable, the structure is simple, and the maintenance is convenient and quick.

4. The shaft is a fully enclosed structure, which ensures that it does not come into contact with the medium, does not rust, and has a long service life.

Scope of application:

It is suitable for industrial and urban water supply and drainage, high-rise building pressurized water supply, garden sprinkler irrigation, fire pressurization, long-distance water supply, heating, bathroom and other cold and warm water circulation pressurization and equipment matching, etc., especially suitable for small boiler water supply.

Technical Parameters:

Flow rate: 6.3-300m3/h;

Head: 13-650m;

Power: 2.2-400KW;

Speed: 1450-2950r/min;

Caliber: φ50-φ200;

Temperature range: ≤105℃;

Working pressure: ≤3.0Mpa.

Performance parameter table:

| 型号 | 流量 | 扬程 | 转速 | 功率(kw) | 效率% | 允许汽蚀余量m | |

| m 3 /h | m | r/min | 轴功率 | 电机功率 | |||

| 50D8×2 | 18 | 19 | 2950 | 1.5 | 2.2 | 62 | 2.3 |

| 50D8×3 | 18 | 28.5 | 2950 | 2.25 | 3 | 62 | 2.3 |

| 50D8×4 | 18 | 38 | 2950 | 3 | 4 | 62 | 2.3 |

| 50D8×5 | 18 | 47.5 | 2950 | 3 .75 | 5.5 | 62 | 2.3 |

| 50D8×6 | 18 | 57 | 2950 | 4.5 | 5.5 | 62 | 2.3 |

| 50D8×7 | 18 | 66.5 | 2950 | 5.25 | 7.5 | 62 | 2.3 |

| 50D8×8 | 18 | 76 | 2950 | 6 | 7.5 | 62 | 2.3 |

| 50D8×9 | 18 | 85.5 | 2950 | 6.75 | 7.5 | 62 | 2.3 |

| 50D8×10 | 18 | 95 | 2950 | 7.5 | 11 | 62 | 2.3 |

| 50D8×11 | 18 | 104.5 | 2950 | 8.25 | 11 | 62 | 2.3 |

| 50D8×12 | 18 | 114 | 2950 | 9 | 11 | 62 | 2.3 |

| 80D12×2 | 32.4 | 22.7 | 2950 | 2.68 | 3 | 75 | 2.8 |

| 80D12×3 | 32.4 | 34.05 | 2950 | 4.02 | 5.5 | 75 | 2.8 |

| 80D12×4 | 32.4 | 45.4 | 2950 | 5.36 | 7.5 | 75 | 2.8 |

| 80D12×5 | 32.4 | 56.75 | 2950 | 6.7 | 7.5 | 75 | 2.8 |

| 80D12×6 | 32.4 | 68.1 | 2950 | 8.04 | 11 | 75 | 2.8 |

| 80D12×7 | 32.4 | 79.45 | 2950 | 9.38 | 11 | 75 | 2.8 |

| 80D12×8 | 32.4 | 90.8 | 2950 | 10.72 | 15 | 75 | 2.8 |

| 80D12×9 | 32.4 | 102.15 | 2950 | 15 | 75 | 2.8 | |

| 80D12×10 | 32.4 | 113.5 | 2950 | 13.4 | 15 | 75 | 2.8 |

| 80D12×11 | 32.4 | 124.85 | 2950 | 14.74 | 18.5 | 75 | 2.8 |

| 80D12×12 | 32.4 | 136.2 | 2950 | 16.08 | 18.5 | 75 | 2.8 |

| 100D16×2 | 54 | 35.2 | 2950 | 7.2 | 11 | 71.5 | 3.3 |

| 100D16×3 | 54 | 52.8 | 2950 | 10.8 | 15 | 71.5 | 3.3 |

| 100D16×4 | 54 | 70.4 | 2950 | 14.4 | 18.5 | 71.5 | 3.3 |

| 100D16×5 | 54 | 88 | 2950 | 18 | 22 | 71.5 | 3.3 |

| 100D16×6 | 54 | 105.6 | 2950 | 21.6 | 30 | 71.5 | 3.3 |

| 100D16×7 | 54 | 123.2 | 2950 | 25.2 | 30 | 71.5 | 3.3 |

| 100D16×8 | 54 | 140.8 | 2950 | 28.8 | 37 | 71.5 | 3.3 |

| 100D16×9 | 54 | 158.4 | 2950 | 32.4 | 37 | 71.5 | 3.3 |

| 100D16×10 | 54 | 176 | 2950 | 36 | 45 | 71.5 | 3.3 |

| 100D16×11 | 54 | 198.6 | 2950 | 39.6 | 55 | 71.5 | 3.3 |

| 100D16×12 | 54 | 211.2 | 2950 | 43.2 | 55 | 71.5 | 3.3 |

| 125D15×2 | 108 | 40 | 2950 | 15.6 | 18.5 | 76 | 4 |

| 125D15×3 | 108 | 60 | 2950 | 23.4 | 30 | 76 | 4 |

| 125D15×4 | 108 | 80 | 2950 | 31.2 | 37 | 76 | 4 |

| 125D15×5 | 108 | 100 | 2950 | 39 | 45 | 76 | 4 |

| 125D15×6 | 108 | 120 | 2950 | 46.8 | 55 | 76 | 4 |

| 125D15×7 | 108 | 140 | 2950 | 54.6 | 75 | 76 | 4 |

| 125D15×8 | 108 | 160 | 2950 | 62.4 | 75 | 76 | 4 |

| 125D15×9 | 108 | 180 | 2950 | 70.3 | 90 | 76 | 4 |

| 125D15×10 | 108 | 200 | 2950 | 78 | 90 | 76 | 4 |